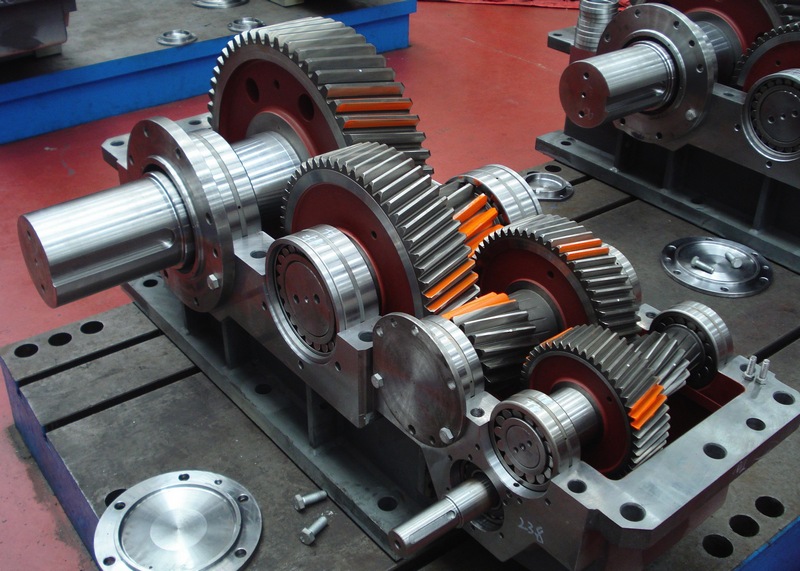

Extruder Gearbox reconditioning:

Inspecting a gearbox on an extruder to determine the necessity of repair or replacement has been a time-consuming and challenging task up to this point. It is tempting to let a gearbox run and not take any action until audible changes, such as rattling or squeaking, or noticeable vibration, are detected. Even when you think you’ve identified the problem, it is still possible that the issue lies elsewhere. This means that you have to shut the machine down again, causing further delays in production.

Electronic gearbox condition monitoring is a cost-effective and beneficial new feature we have introduced on our twin-screw extruders for both the food and powder coating industries. This technology allows us to monitor the condition of the gearbox in real-time and make adjustments when necessary, ensuring optimal performance and extended service life.

This system continuously tracks the frequency and amplitude of vibrations in the gearbox, enabling the ongoing condition of essential components to be assessed. It functions similarly to an experienced engineer, who would listen and feel the gearbox for any signs of distress; however, this system can detect issues much earlier than a human could. Additionally, it is low-cost and easy to use.

The Gear Services extruder gearbox self-monitoring system utilizes a “traffic light” system of green, amber, and red signals to indicate whether the gearbox is operating within limits requires inspection or maintenance, or needs urgent attention. The system is pre-calibrated to provide an easy-to-understand representation of the gearbox’s condition. It is able to detect problems caused by normal wear or impending failures before they cause a sudden stoppage, thus allowing corrective action to be taken before the business suffers.

Gearbox condition monitoring offers numerous advantages, including reduced downtime, improved maintenance scheduling, comprehensive reporting, data retention, historical trend analysis, and the prevention of unexpected repairs and replacements. Not only is it easy to install and monitor, but it also helps to avoid the costly financial consequences of production breakdowns, as well as to maintain customer confidence.

The Gear Services twin-screw extruders now feature an integrated PLC control system that includes a straightforward system for easy installation as a stand-alone system on existing machines.